For the construction of a new incineration facility in the UK, Dutch Incinerators required a custom-designed powerpack. In this context, the company approached Hydrauvision Systems. During the discussions, it became clear that Dutch Incinerators was also seeking a reliable partner for the electrical engineering and the manufacturing of power distribution and control panels.

Hydrauvision subsequently introduced Technotron as a suitable party for this scope. This marked the beginning of a close and successful collaboration.

The Project

The installation involves an advanced incineration system designed for the treatment of difficult-to-process waste materials. Dutch Incinerators, a Dutch company with proprietary technology, develops systems that incinerate waste at extremely high temperatures. As a result, residual waste is reduced to an absolute minimum. Emissions are treated using modern filtration systems that meet strict environmental standards. The entire installation is controlled by a PLC-based automation system.

Initiation of the Collaboration

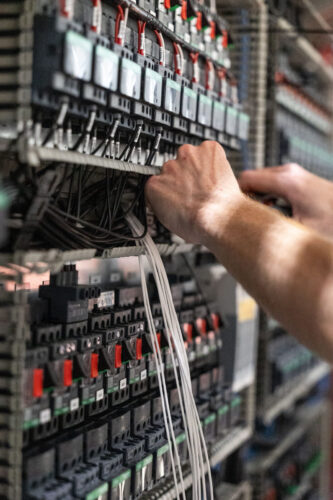

The initial meeting served to explore the potential for cooperation. Thanks to relevant reference projects and in-house expertise, Technotron quickly earned the confidence of Dutch Incinerators. This led to an order for translating the provided P&ID drawings into electrical schematics and panel layouts – specifically for the PLC/remote I/O panels and power distribution cabinets.

Our Approach

Engineering and Design Phase

During the engineering phase, it became clear that the P&IDs provided were still under development. Due to Technotron’s early involvement, a close collaboration was established, allowing both parties to work efficiently toward a final concept.

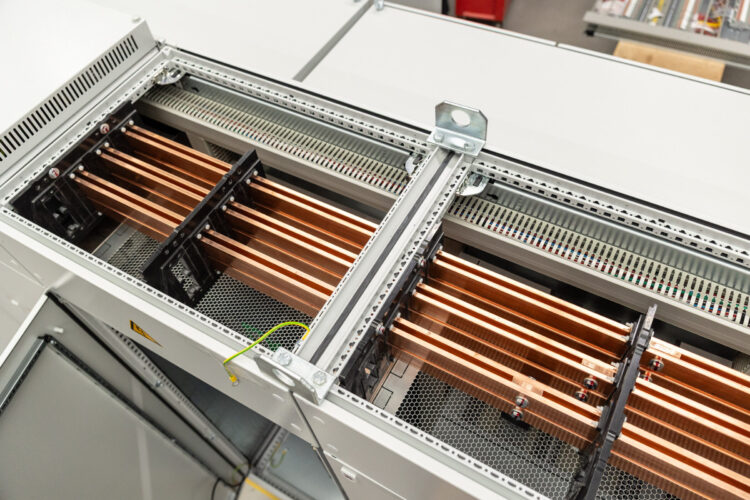

The complete design was developed using EPLAN/ProPanel, taking into account key technical requirements such as thermal management, short-circuit capacity, safety, and redundancy.

Control Panel Assembly

Following the completion of the design phase, Technotron submitted a proposal for the panel assembly. The total panel scope includes:

- one main power distribution panel

- one MCC (Motor Control Center) panel

- and nine field-mounted remote I/O panels

Current Status and Next Steps

The panels are currently being assembled at our production facility. Once completed, all systems will undergo comprehensive testing, including full wiring checks and, where applicable, functional testing of the power and distribution systems (excluding software).

At a later stage, third-party developed software will be integrated. From the end of September, Dutch Incinerators will be on-site at our workshop to carry out live system testing. Once successfully completed, the panels will be shipped to the final project location in the United Kingdom.