What is Motor Circuit Analysis?

Motor Circuit Analysis is a non-destructive testing method using a low test AC voltage (100-800 Hz) to examine electrical machines and accessories (cables, connections, windings, etc.) at a very early stage for the development and presence of potential faults. From the performed MCA measurements, measured value interpretation and data analysis, a targeted prediction can be made about the occurrence, presence and severity of the potential fault(s).

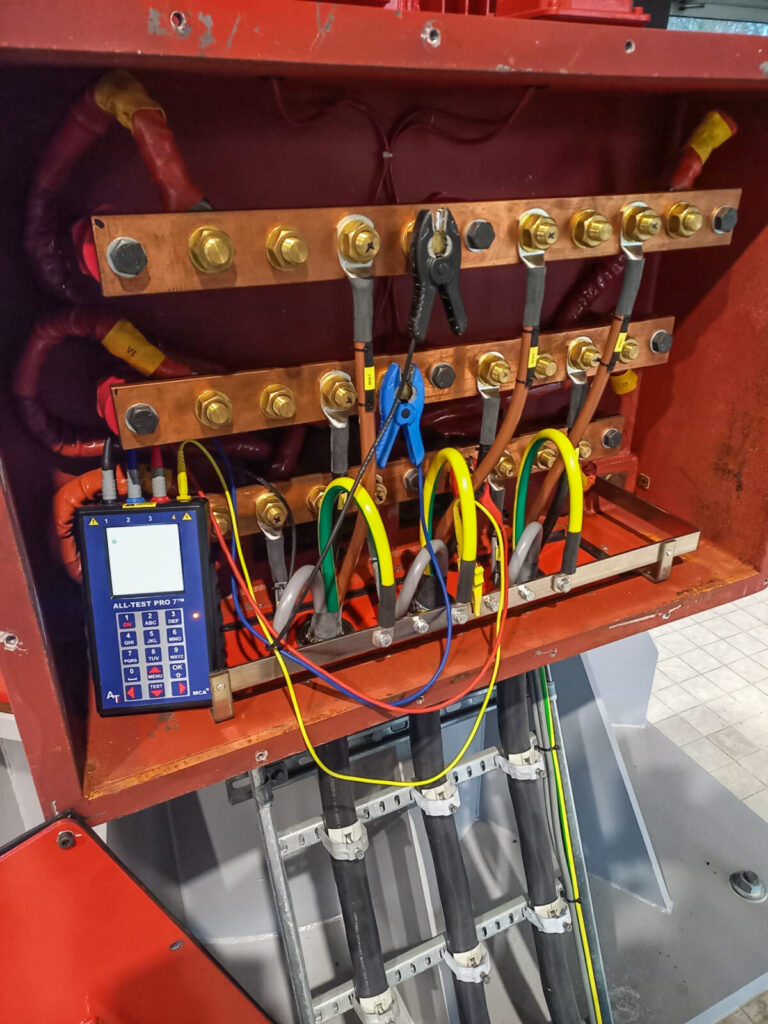

The MCA inspection can be performed directly from the Motor Control Centre (MCC), or directly at the motor terminals themselves. The advantage of testing from the MCC is that this allows the entire motor circuit, i.e. including the connections, motor cables, safe working switches in the main circuit, etc. between the test point and the motor, to be measured and evaluated.

The method is part of every World-class Maintenance Programme and is used as predictive maintenance to ensure equipment reliability and availability, in solving acute problems, and to estimate time-to-failure.

Why a MCA inspection?

Het doel van een MCA onderzoek is om met behulp van Motor Circuit Analysis inspectieapparatuur in een zéér vroeg stadium het ontstaan van onvolkomenheden en/of “potentiële” fouten in elektrisch equipment (motoren, generatoren, spoelen, transformatoren e.d.) te detecteren en te identificeren.

Predictief MCA onderzoek stelt u in staat om tijdig en op planmatige wijze de gepaste “correctieve” onderhoudsactiviteiten uit te voeren. Het uitvoeren van een MCA onderzoek op periodieke basis draagt bij aan het verhogen van de betrouwbaarheid, de kwaliteit, de beschikbaarheid en de veiligheid van de productie installaties.

What errors can be found with MCA research?

Stator Winding “Failure Modes”

The primary cause of electric motor winding faults is caused by electrical short circuits, such as:

- Short circuit between winding wires among themselves of a coil (turn-to-turn short)

- Short circuit between coils of one phase (coil-to-coil short)

- Short circuit between coils of different phases (phase-to-phase short)

- Open phases

- Burnt and/or contaminated windings

- Short circuit from winding(s) to earth

Rotor “Failure Modes”

- Interrupted rotor cage bars and/or casting faults

- Rotor eccentricity

- Rotor air gap deviation

Connection "Failure Modes"

- Cable faults (earth faults, “loose” connections and/or open joints)

- Transition resistance Safe Work Switch contacts

- Component faults (from MCC to motor: cabling – relays -SWS- etc.)

The listed Failure Modes can be caused by a single problem or by a combination of several problems, such as:

- Thermal problems (ageing, overload and/or varying load)

- Mechanical problems (movement, rotor and/or components)

- Electrical problems (dielectric stress, corona and/or transients)

- Environmental influences (humidity, contamination and/or foreign objects)